Heat, and industrial process heat in particular, is a huge driver of carbon emissions and is wildly underserved as a vector for decarbonisation (putting it in the bullseye for Climate Podnotes). There are a number of low-carbon heat sources that can be brought to bear from heat pumps, to nuclear, to biomass, to solar thermal, to hydrogen. Rondo Energy is using indirect heating, using resistance heating wire (like in your toaster) to super heat bricks to store and then delivery heat energy. They recently made a splash with the announcement of their $22mm Series A from Breakthrough Energy Venture and Energy Impact Partners. I listened to CEO John O’Donnell on the Bigger Than Us podcast. Whilst increasingly it is possible to electrify industrial heat, direct electrification requires constant electricity flow (for most applications) with limited capacity to demand shift and potentially requires processes to be re-engineered. Rondo’s drop-in solution overcomes renewables’ intermittency issues with the thermal storage and also allows it to provide services to the electrical grid. It also uses abundant, cheap materials without needing to build out a new industrial base or compete for critical minerals. Rondo, we are rooting for you.

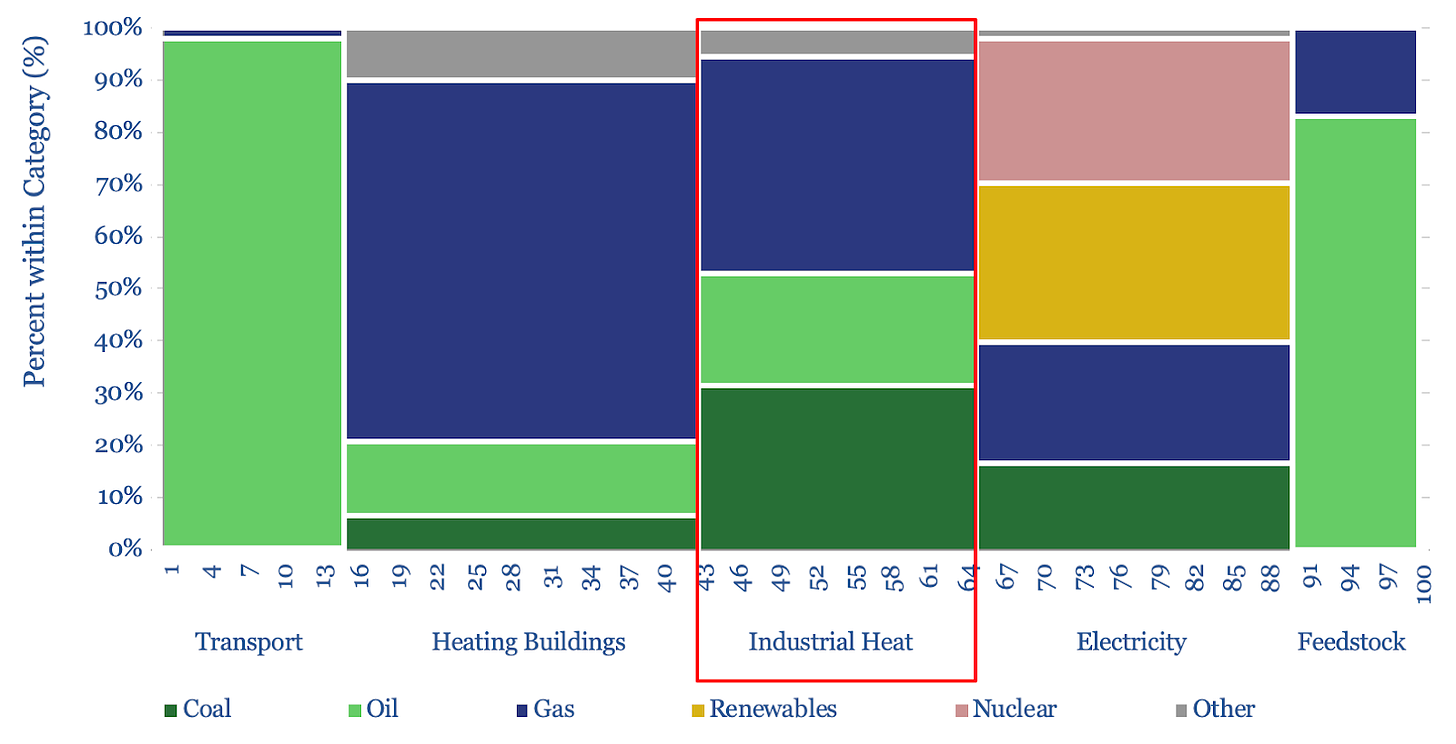

Industrial heat represents a big chunk of energy use (circa 20% globally) and emissions (circa 10% globally). Pretty much all of that is currently from combustion of fossil fuels. Below is one of my favourite charts from the excellent Rob West of Thunder Said Energy, which shows the big chunk of the pie industrial heat represents (as well as revealing just how much work there is still to do outside of electricity generation).

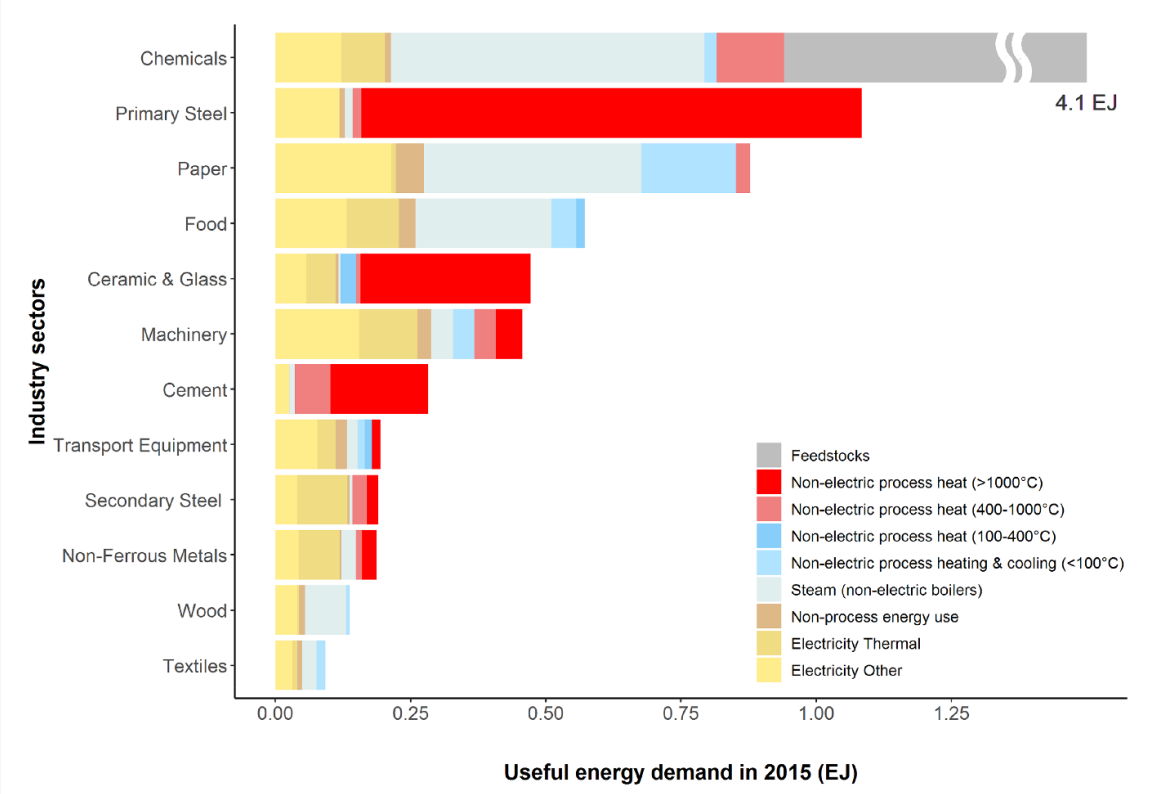

Here is a breakdown of the energy use within various industries in Europe. Note that alongside the obvious sectors with high-temperature heat in steel and cement, there is significant energy use for steam in chemicals, pulp and food.

From a geopolitical standpoint, it is now critical to start addressing industrial heat. German industry uses about 40% of natural gas in the country for example.

Industrial heat traditionally has been deemed “hard to decarbonise” – it is cost sensitive, competing against cheap fossil fuel, and processes have particular temperature and volume requirements.

What’s changed? Wind and solar have become the lowest cost source of energy in many places in the world.

Rondo is building a drop-in electrical boiler or furnace, converting intermittent renewable to constant heat delivery. It combines two old technology – resistance heat wires and blast furnaces – using electric heat to superheat bricks that give off constant heat.

Rondo’s solution can serve 90% of industrial heat requirements.

High temperature bricks are made from different materials in different places. One example - bauxite + sand combined in a cement kiln. It would be possible to manufacture enough of these bricks to reduce 15% of emissions using just 1% of cement kiln capacity.

Rondo uses earth abundant materials so it doesn’t compete for raw materials with batteries.

In California alone, to replace industrial heat use entirely with electricity would require 100GW of solar PV capacity. If it is used for heat it doesn’t need to be connected to the grid, avoiding a massive bottleneck for continued rapid build out of renewables. Interconnection delays for grid connection – 7.5 years in California, 10 years in Oklahoma. Most of the 100GW that is required to decarbonise industrial heat doesn’t need to be grid connected, enabling time to permit and build to be brought down to 2.5 years.

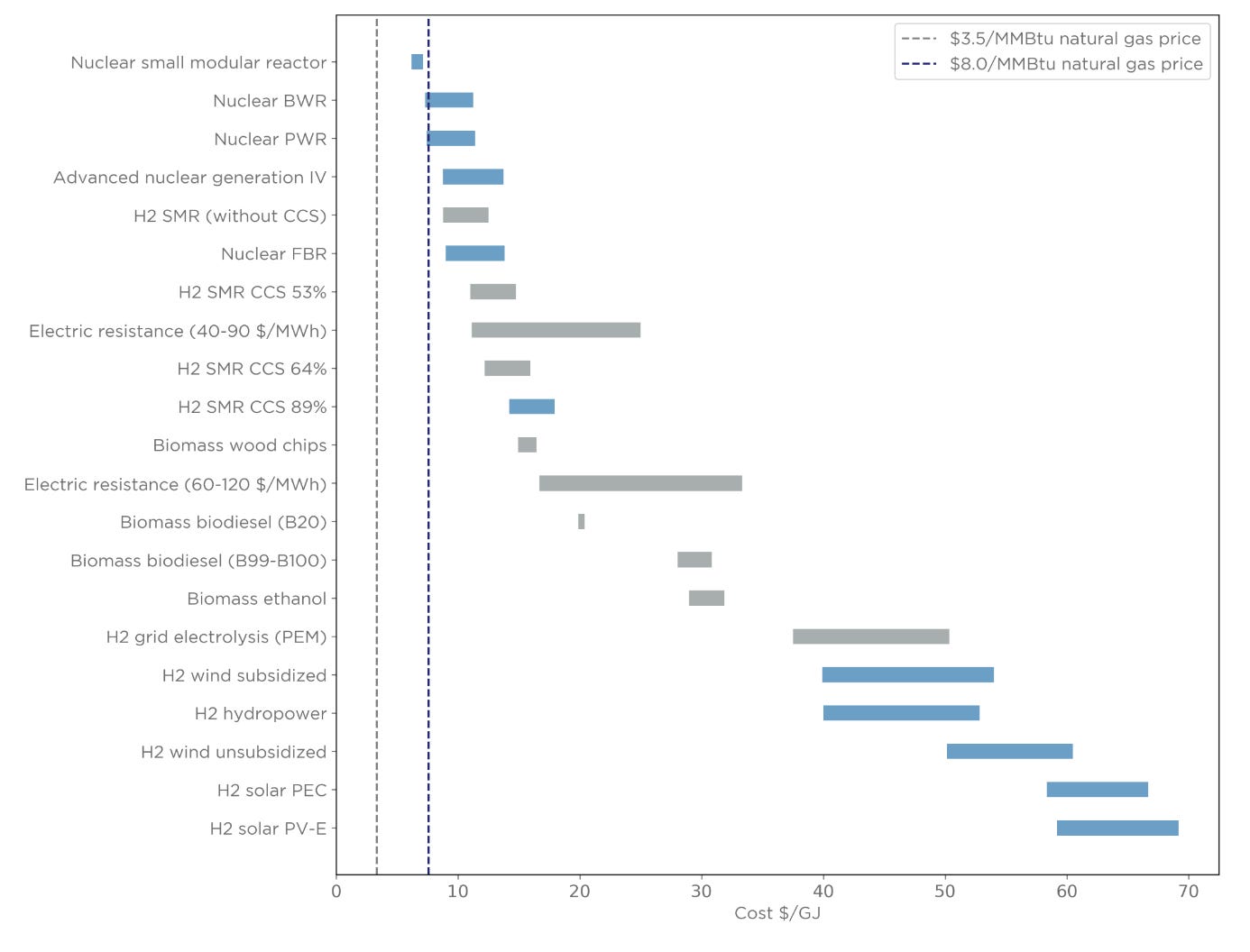

The main competing technology for this challenge of turning intermittent renewable electricity into dispatchable high-grade heat is hydrogen. But H2 use has 50% efficiency for heat, vs 98% efficiency for Rondo. H2 also has other valuable uses like chemical input that should be prioritised ahead of heat production. Note the green H2 taking up the top end of the cost curve (although these from two years ago so will have come down a bit):

Indirect electrification – moves away from the assumption that things need to be fed directly by electricity, e.g. electric arc furnaces for steel, to the idea that you can load shift electricity to deliver constant. This reduces peak load requirements, provides services to the grid, and reduces the capex requirements for industrials switching to low carbon, as it’s drop in. There is still a need to upgrade electrical infrastructure, but doesn’t require reorganising industrial processes.

Rondo’s vision is a future where decarbonisation is cheaper than business as usual, where industry moves to where the lowest cost renewable resources are, not to where the slackest carbon markets are.