Heirloom: DAC via mineralisation

My Climate Journey - DAC via mineralisation w. Heirloom

Picking up on the CDR (carbon dioxide removal) thread from last week, I dug out an old MCJ episode with the founders of Heirloom, one of the carbon removal companies that Nan Ransohoff of Stripe mentioned in that conversation. Heirloom got a good leg up with an enthusiastic announcement by Julio Friedman on their launch earlier in the year, and, indeed, the founding team has an outstanding pedigree, of the sort that makes one optimistic about the progress that is going to be made in this area in the coming years. There is quite a bit of general content around CDR which was covered in last week’s Notes, so I’m focussing on the Heirloom-specific stuff mostly here.

The founding team brings extremely strong credentials to the table. Noah McQueen, the head of research, worked alongside Dr Jennifer Wilcox, who is now Principal Deputy Assistant Secretary (a title that just rolls off the tongue) at the Office of Fossil Energy and Carbon Management at the DoE and is generally recognised as one of the foremost academics in the carbon capture and removal space.

Perhaps more interestingly, Shashank Samala, the CEO, is a co-founder of Tempo Automation, a venture-backed automated manufacturing platform for electronics, including complicated things like components for the Mars Rover.

Shashank also used be Entrepreneur in Residence at Carbon180, a CDR advocacy group. It’s encouraging to hear that there is a tight feedback loop between the policy experts and the entrepreneurs in this emerging space.

This team combination speaks to the dual challenges of scaling CDR - the chemical engineering challenge of separating out a highly dilute stream of CO2 from the atmosphere, and the industrial scale up challenge of maximising the learning rate (the cost reductions per cumulative doubling - or Wright’s law).

The question of moral hazard around CDR comes up again - part of the thoughtful answer is that understanding the actual costs of carbon clean-up through CDR, can crystallise and accelerate some decisions on avoidance and reduction.

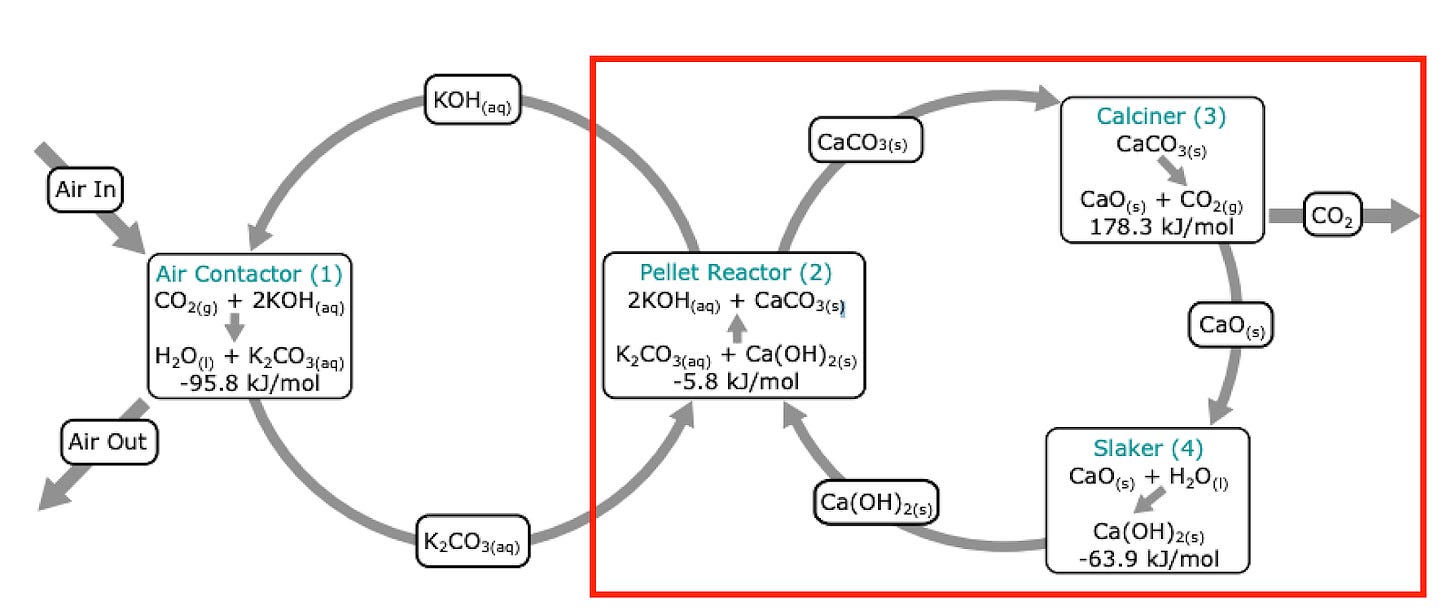

Heirloom’s technology works on the natural mechanism of calcium- and magnesium-oxides binding with atmospheric carbon to form carbonates - most commonly encountered as calcium carbonate or limestone. Formula: CaO + CO2 -> CaCO3

The calcium (or magnesium) oxide is produced by heating the calcium carbonate up to 900 degrees C using a bit of kit called a calciner, and then capturing the CO2 that is separated. The oxide is then distributed in a way to maximise the rate of reaction with atmospheric CO2.

This process is similar to one of the two chemical processes that Carbon Engineering uses in their direct air capture facility - more of which can be found in Keith et al’s Joule article, image below. CE uses an additional process with potassium hydroxide for the air-capture piece. This officially puts me out over my skis on the chemistry, but if any readers have an explanation of the benefits of the different approaches, I’d be delighted to understand.

Heirloom’s process is also similar to the one used by Origen Carbon Solutions, spun out of Oxford and now run by friend and fellow reformed investment banker, Ben Turner. Origen are focussed initially on the carbon capture piece (point-source) from the production of lime (a calcium oxide) from limestone.

There has been a massive change in the levels of government support of CDR research since the Biden administration.

There remains a gap to be filled with entities that will build the geological storage capacity and also monitor it on an on-going basis.