One of the things that brings me hope on climate action is that collectively we continue to manage to innovate our way to lower cost and higher efficiency, even though we can’t anticipate where those innovations might come from. (Hence the nonsense of bottom-up long-term cost curve estimates.) Often new possibilities are unlocked when falling cost curves of certain technologies unlock new business models or adjacent applications (think gmail being launched anticipating low-cost storage, expanded applications for LEDs, etc). Erthos have identified the fact that the falling cost of solar panels has flipped the logic of plant and is allowing them to reimagine utility scale solar. I was particularly intrigued to dig into this after hearing Ion Yadigaroglu of Capricorn Investments say that it might be the most impactful investment for decarbonisation that they’ve ever made. (Comments in the press release for the Capricorn-led $17.5mm series B.) This from early backers of Tesla.

Erthos has developed a new way of building utility scale solar projects by laying them flat on the ground. According to the company, this allows them to cut the cost of a solar farm by 20%.

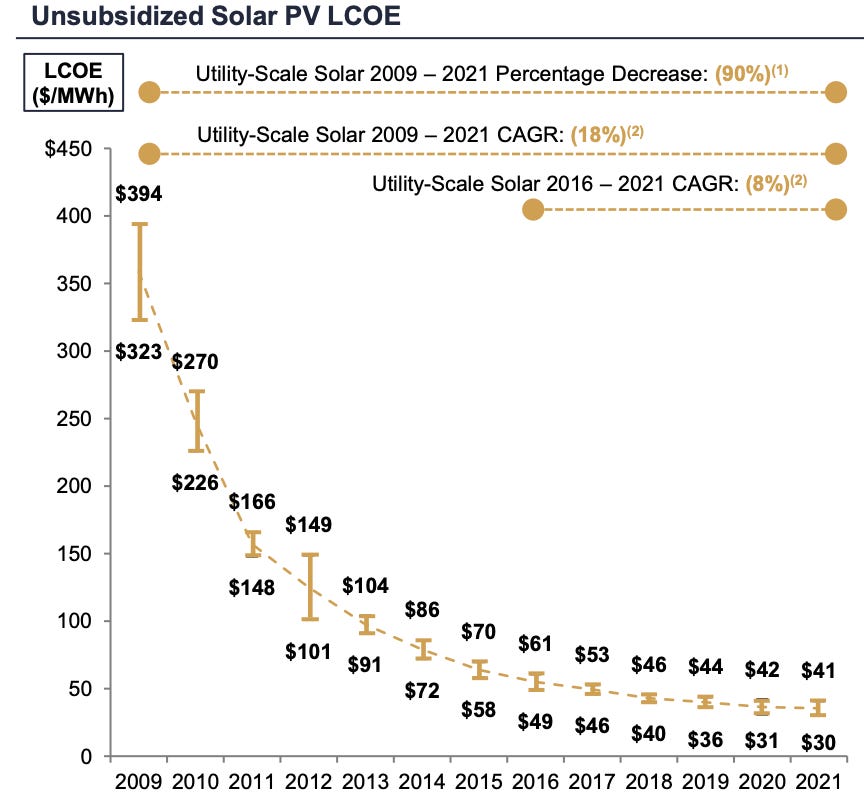

The levelised cost of electricity (LCOE) of utility scale solar has dropped by 90% over the last 12 years, but improvements in recent years have been more marginal.

There are now typically hundreds of developers bidding for a project with fairly commoditised pricing because everyone is using the same kit, with the difference in final pricing determined by risk appetite.

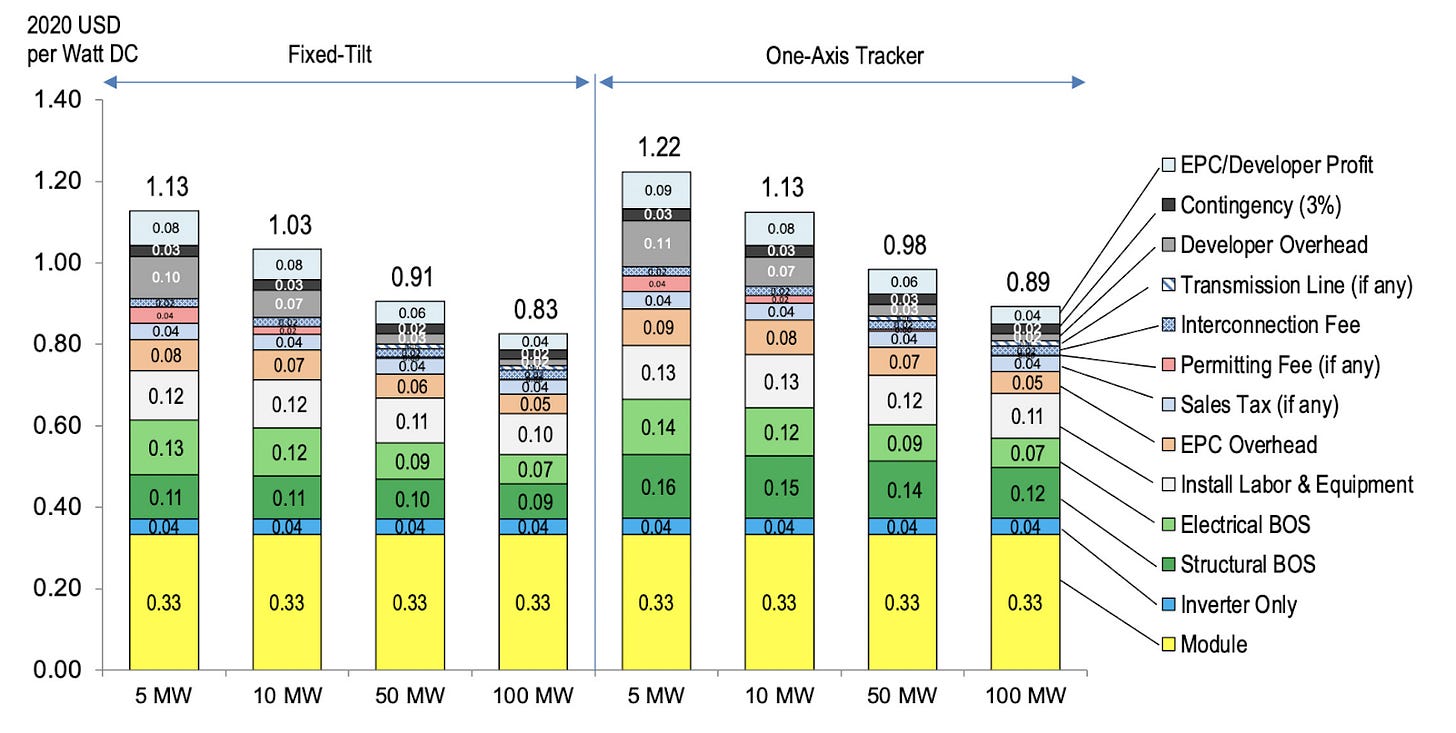

In 2013, trackers were introduced and flipped from 10% to 90% of market in 2 years, because back then the modules were sufficiently expensive that it made sense to have more capex in the tracker to a get a bit more energy out of the module.

The key insight that enabled Erthos’s innovation is that, with the cost of solar panels dropping, at a certain point (38c / kw), it no longer makes sense to optimise the output per panel. You just buy more panels.

So, whilst each panel generates a bit less electricity than it would do with a tracker (about 20% less), by getting rid of the steel, the motors, much of the cabling, etc, it comes out cheaper and enables between double and triple the amount of electricity generated per unit of land. [Land utilisation will become increasingly important as renewables continue to scale.]

Where does the 20% cost reduction figure come from? According to this study from the National Renewable Energy Lab (NREL), the racking accounts for between 10-14% depending on whether it is fixed or tracker, so that is a straight cut. There are also costs taken out of the electrical BOS (balance of system) as they use 70% less cabling and out of the labour as it takes half the time to build.

Ethos plants can be laid across undulating land (up to 15 degree of tilt) so can minimise civil engineering and ground prep.

By placing the modules on the ground, there is less thermal stress; the ground acts as a heat absorber, reducing micro-cracking and extending module life.

Whilst there is increased soiling by being on the ground, the design allows for automated daily cleaning with a robot, which not only cleans it, but also simultaneously scans up close for any damage. That compares to drone inspection of typical mounted solar farms that might only happen twice a year.

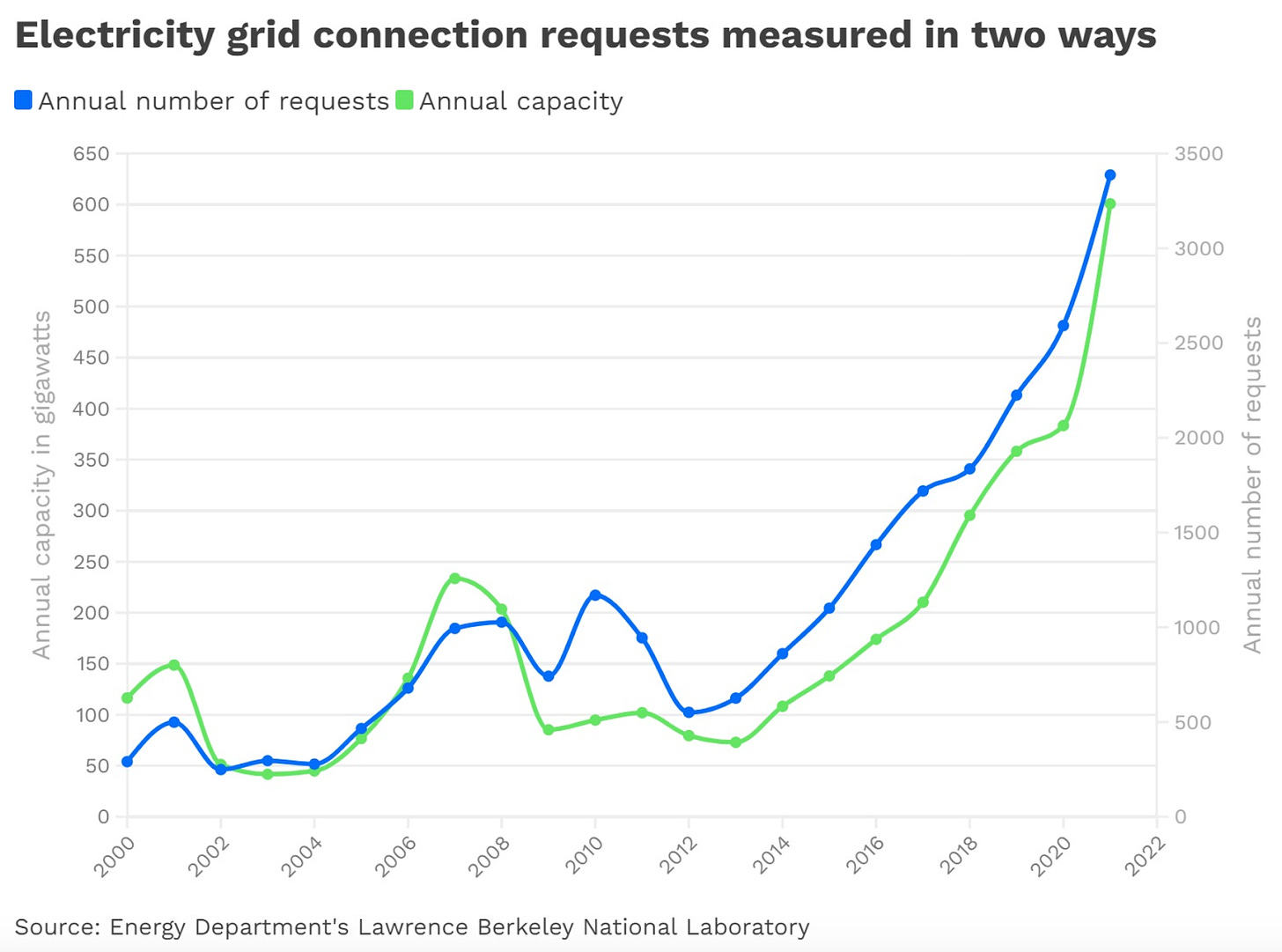

It strikes me that a step change in cost / time / land usage for these developments might only exacerbate the challenges with connecting to the grid (excellent article from Canary Media on that here) where queue times are now extending out 4 years in the US.

In a world where the projects themselves become cheaper and quicker to build, developers will find more ways around the interconnector bottleneck by co-locating it with demand, be it microgrids, data centres, or things like electrifying industrial heat or green H2 generation (note Electric Hydrogen’s just-announced $198mm round).